Your Cart is Empty

Easter Sale! 5% Off All Orders with Code “EASTER5” – Ends Midnight Tuesday, April 22nd!

Easter Sale! 5% Off All Orders with Code “EASTER5” – Ends Midnight Tuesday, April 22nd!

INDUSTRY

ABOUT US

What is a Hotwire Anemometer? Essential Guide to Airflow Measurement

by Curtis Treloar December 28, 2023 9 min read

What is a Hotwire Anemometer? Essential Guide to Airflow Measurement

A hotwire anemometer is a precise and sensitive instrument used to measure fluid flow, typically gas or air velocities. It works on the principle of heat transfer through convective cooling, where the rate of heat loss is dependent on the speed and characteristics of the fluid flow. Hotwire anemometers are widely used in various industries, including aerospace, automotive, and environmental applications, due to their high accuracy and responsiveness.

The principles of operation for a hotwire anemometer involve passing an electric current through a thin wire which is exposed to the fluid flow. As the fluid moves across the wire, it carries away heat, causing the wire's temperature to decrease. This change in temperature directly corresponds with the fluid velocity. The hotwire anemometer measures this change and calculates the fluid velocity accordingly.

There are various types of hotwire anemometers available, differing mostly in their design and components. Some common components include the sensor element, measurement bridge, and signal conditioning electronics. These anemometers are often selected based on their intended usage, sensitivity requirements, and durability. Maintenance and calibration are critical for ensuring the accuracy of measurements, typically involving cleaning the sensor and comparison against a reference standard.

Key Takeaways

- Hotwire anemometers are used to measure fluid velocities using heat transfer principles.

- They operate through a temperature change that corresponds with fluid velocity.

- Different types vary in design and components, with maintenance and calibration essential for accuracy.

Principles of Operation

Thermal Properties

A Hotwire Anemometer operates based on the concept of heat transfer through convection. The principle behind this involves a heated wire or filament that is exposed to an airflow. As the air flows over the wire, it causes the filament to cool down. The change in temperature of the wire is closely related to the air velocity. It is essential to note that the relationship between temperature and airspeed depends on the thermal properties of the wire material, such as its thermal conductivity and heat capacity.

Electric Current Flow

The electrical aspect of a Hotwire Anemometer's operation relies on two main principles: the wire's electrical resistance and the connection of the wire to a Wheatstone bridge circuit. The filament's resistance changes with temperature variations, and this relationship is described by the temperature coefficient of resistance (TCR), which varies for different wire materials. Common materials used for filaments include platinum, nickel, and tungsten.

A Wheatstone bridge circuit connects the heated wire (or sensor element) and measures the resistance changes caused by temperature variations. The circuit provides a voltage output proportional to the difference in resistance between the sensor and the other elements in the bridge. The voltage signal can be further processed and converted into a signal representing the air velocity.

To summarise, a Hotwire Anemometer utilises the principles of thermal properties and electric current flow to measure air velocity. Through the heat transfer and electrical resistance changes, the device is able to provide an accurate representation of airflow speeds.

Types of Hotwire Anemometers

There are several types of hotwire anemometers used to measure the velocity and volume of fluid flow. In this section, we will discuss two common types: Constant Current and Constant Temperature hotwire anemometers.

Constant Current

The constant current hotwire anemometer, also known as the Constant Power Anemometer, works by maintaining a constant electrical current through the hotwire sensor. As the fluid flow increases, heat is drawn away from the wire, causing a change in temperature. This change in temperature produces a change in resistance, which is proportional to the fluid velocity.

Some advantages of constant current hotwire anemometers include:

- Simplicity: The design and operation of constant current anemometers are relatively simple, making them easy to implement and understand.

- Economical: They are generally more affordable than their constant temperature counterparts.

However, it is important to note that constant current anemometers have some limitations:

- Slower response time: Due to the need for constant current adjustments to maintain a stable temperature, the response time can be slower than constant temperature hotwire anemometers.

- Accuracy: The accuracy of a constant current anemometer may be affected by the specific heat of the fluid being measured, necessitating more frequent calibrations to maintain reliable measurements.

Constant Temperature

A constant temperature hotwire anemometer operates by maintaining the temperature of the hotwire sensor at a constant level above the fluid temperature. It does this by continuously adjusting the electrical current to compensate for changes in fluid flow. As the fluid velocity increases, the required current to maintain the constant temperature also increases. This current change is directly proportional to the fluid velocity, allowing for a precise measurement.

Constant temperature hotwire anemometers have some key advantages:

- Fast response time: Due to the continuous current adjustments, constant temperature hotwire anemometers offer quicker response times than constant current anemometers.

- High accuracy: As these anemometers are less sensitive to specific heat variations, they tend to offer better measurement accuracy.

However, constant temperature hotwire anemometers also have their drawbacks:

- More complex: The circuitry and operation of constant temperature anemometers can be more intricate, making them more challenging to implement and troubleshoot.

- Higher cost: These anemometers are generally more expensive than constant current anemometers.

In summary, both constant current and constant temperature hotwire anemometers are valuable tools for measuring fluid flow. The choice between them depends on the specific application requirements, budget, and accuracy needed for the task at hand.

Design and Components

Sensor Element

A Hotwire Anemometer utilises a thin wire as its sensor element, which is typically made of materials like tungsten or platinum. The wire's diameter usually ranges from 2 to 10 micrometres and is coated with ceramic material for protection against corrosion. The sensor wire is then mounted on a support structure, often made from a non-conductive material, such as quartz or ceramic. This allows for minimal interference on the measurements and ensures an accurate response to the airflow.

The sensor element works on the principle of convective heat transfer. In essence, the wire is heated to a temperature greater than the ambient temperature. As air flows over the heated wire, the heat transfers from the wire to the airflow, leading to a cooling effect on the wire. The rate of cooling is directly related to the airflow's velocity, which allows for the measurement of airspeed.

Supporting Circuitry

The supporting circuitry of a hotwire anemometer is responsible for powering the sensor element and processing the changes in electrical properties resulting from the heat transfer. The most commonly used configurations are:

-

Constant Temperature Anemometer (CTA): In this design, the circuitry maintains the wire at a constant temperature. As air flows over the wire, the circuitry adjusts the current passing through the wire to keep it at the set temperature. The voltage needed for the adjustments is directly proportional to the airflow velocity. The CTA offers a rapid response time and high sensitivity, making it suitable for turbulence measurements.

-

Constant Current Anemometer (CCA): In a CCA, the circuitry provides a fixed current to heat the sensor wire. As airflow increases, the wire temperature drops, causing the electrical resistance to change. The change in voltage across the wire is then used to determine the airspeed. The CCA setup is generally less sensitive and slower in response compared to the CTA, but it is more stable and durable.

Both the CTA and CCA systems require additional components, such as amplifiers, filters, and analogue-to-digital converters, to process and display the measured data. These components form an integral part of the anemometer, ensuring accurate and reliable readings.

Usage and Applications

A Hotwire Anemometer is an essential instrument in various fields, due to its accurate and sensitive measurement of air flow velocities. This section delves into the diverse usage and applications of hotwire anemometers.

In the aerospace industry, hotwire anemometers extensively help in evaluating the performance characteristics of aircraft components such as wings, engines, and fuselage. Often integrated into wind tunnel testing environments, they provide vital data for designing more efficient and safer aircraft.

The automotive sector similarly benefits from the precision of hotwire anemometers in measuring air flow patterns around vehicles. Engineers utilise this information to optimise vehicle aerodynamics, reduce drag, and ultimately enhance fuel efficiency. Additionally, hotwire anemometers can be employed for evaluating HVAC systems in cars, ensuring comfortable and consistent cabin conditions.

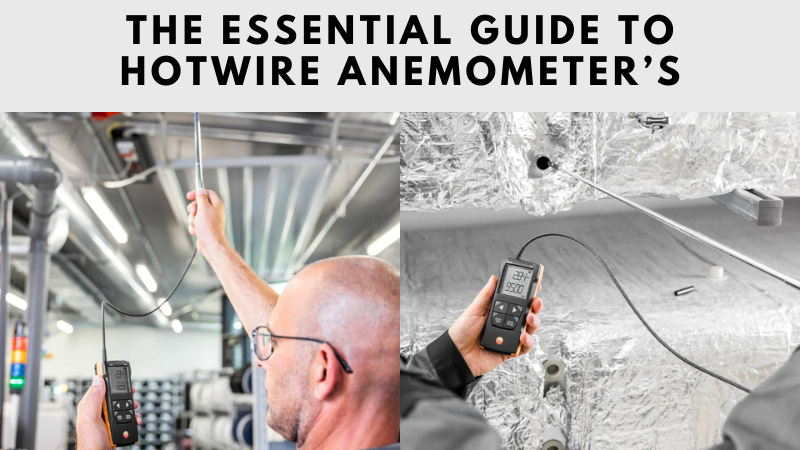

Regarding industrial applications, hotwire anemometers have a significant presence. They assess ventilation systems and ductwork in factories and plants, assisting in maintaining air quality standards and energy consumption efficiency. Proper air flow management also aids in safeguarding worker health by mitigating hazards such as fumes, dust, and dampness.

Notable environmental uses include air quality monitoring, wind resource assessment, and pollutant dispersion research. Hotwire anemometers contribute to a better understanding of wind behaviour patterns, helping in weather forecasting, planning wind farms, and monitoring emissions.

Given their accuracy and versatility, it is no wonder that hotwire anemometers find their place in a variety of applications, from aerospace to environmental monitoring. These indispensable tools have become essential assets for professionals seeking detailed air flow data to improve and optimise their projects.

Maintenance and Calibration

Regular maintenance and calibration are essential for ensuring the accuracy and reliability of a hotwire anemometer. This section provides a brief overview of the main procedures and considerations for maintaining and calibrating your anemometer.

Cleaning

Over time, a hotwire anemometer can accumulate dirt, dust, and other contaminants that may impair its performance. To avoid this, it is recommended to periodically clean the sensor using the following steps:

- Carefully remove the sensor from the anemometer housing.

- Gently clean the sensor with a soft, damp cloth or a cotton swab.

- Allow the sensor to completely dry before reinstalling it in the anemometer housing.

It's essential to always handle the sensor with care, as it is often delicate and prone to damage.

Inspection

Regular visual inspection of the anemometer can help identify any potential issues before they become serious problems. When inspecting your anemometer, look for:

- Damaged or loose connections.

- Frayed or broken wires.

- Cracked or chipped sensor elements.

- Obstructions or debris in the airflow path.

Calibration

Calibration is vital to ensure accurate and consistent measurements. It is generally recommended to calibrate your anemometer at least once per year, or more frequently depending on the specific application and environmental conditions. Calibration involves comparing the anemometer's measurements with those of a known reference standard, and then adjusting the anemometer's response accordingly.

There are two main methods for calibrating hotwire anemometers:

-

Comparison method: This technique involves placing the anemometer in a controlled flow environment alongside a reference standard anemometer. By comparing the readings from both devices, any necessary adjustments can be made to the hotwire anemometer to align it with the reference instrument.

-

Transfer standard method: In this approach, a calibrated transfer standard anemometer is used to measure the flow at multiple points within the test environment. The hotwire anemometer is then exposed to the same flow conditions, and its measurements are compared to the transfer standard to determine any necessary adjustments.

It is important to conduct calibrations under stable and controlled environmental conditions and to use recognised reference standards to ensure the accuracy of the results.

In conclusion, regular maintenance, inspection, and calibration are essential to the proper functioning and accuracy of a hotwire anemometer. By following these guidelines, users can maintain the reliability and longevity of their anemometers, ensuring accurate measurements and meaningful data.

Frequently Asked Questions

How do hot wire anemometers measure air flow?

Hot wire anemometers measure air flow by exploiting the heat transfer properties of a heated wire. When air flows over the wire, it cools down and the temperature drop of the wire is detected by an internal sensor. The speed of the air flow can be determined by calculating the rate at which the heated wire is cooled.

Can a hot wire anemometer be used for fluids other than air?

While primarily designed for measuring air flow, hot wire anemometers can also be used for other fluids, such as gases and liquids. However, the accuracy and reliability of the measurements may be affected by the specific properties of the fluid, such as density, thermal conductivity, and temperature.

What distinguishes a hot wire anemometer from a pitot tube in measuring airflow?

Both hot wire anemometers and pitot tubes are instruments used for measuring airflow velocity. However, they employ different principles in taking measurements. A hot wire anemometer uses heat transfer to determine the air flow, while a pitot tube measures dynamic pressure of the airflow. Hot wire anemometers provide high sensitivity and are capable of measuring very low velocities, while pitot tubes are generally used for higher velocity ranges.

How does King's law apply to hot-wire anemometry?

King's law is an empirical relationship that is used in hot-wire anemometry to describe the relationship between the voltage output of the anemometer and the air flow velocity. This law combines two parameters – the temperature coefficient and the air velocity – to establish a correlation between the anemometer's output voltage and the actual air speed. By using King's law, the velocity of the air flow can be determined more accurately.

What is the principle behind a constant temperature hot wire anemometer?

In a constant temperature hot wire anemometer, a feedback mechanism is used to maintain the temperature of the heated wire at a constant value. As the air flows over the wire and cools it down, the anemometer adjusts the current flowing through the wire to maintain its set temperature. The current required to do this is proportional to the air speed, enabling the air flow rate to be measured.

In what applications are hot wire anemometers considered the most suitable?

Hot wire anemometers are commonly used in circumstances where accurate and sensitive measurement of air flow is required. Applications include aerodynamics research, meteorology, ventilation system testing, and environmental monitoring. As these devices are capable of measuring very low velocities, they are particularly suitable for applications where detecting small air currents or turbulent flows is critical.

Questions? Give us a call

1300 525 120